Improve inspections, maintenance, and compliance.

Asset compliance obligations are significantly easier to manage with the Condition Monitor feature; a key component of our software platform.

What’s the impact?

What impact can Condition Monitor have?

At Falcker, we focus on delivering tangible operational benefits. With Condition Monitor, tank operators can expect:

Features & Benefits

Large reductions in maintenance costs through early issue detection

Continued compliance with standardization and complete documentation

Extended asset lifespan by addressing corrosion and structural risks early

Enhanced operational efficiency through data-driven maintenance planning

Improved collaboration between inspection and maintenance teams

Drive safer, smarter operations

Condition Monitor empowers tank operators with accurate data and standardized documentation to ensure inspections and maintenance are efficient, safe and fully compliant.

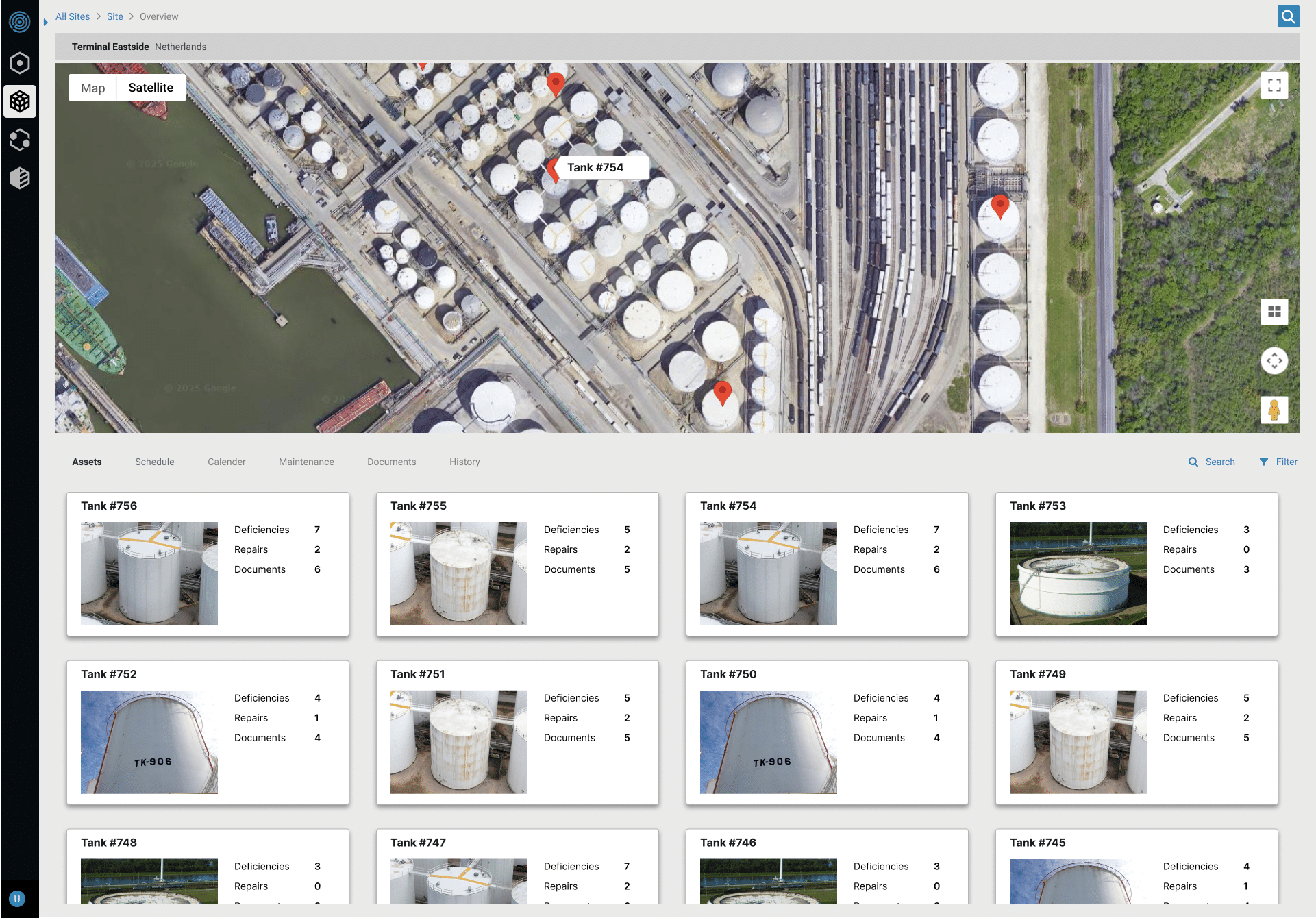

centralized insight, faster decisions

By unifying asset condition data in one platform, teams gain a full view of each tank. Enabling quicker, smarter planning and action across all operations.

Maximize reliability and future-proof performance

With Condition Monitor, organizations can boost asset lifespan, optimize maintenance costs and stay ahead of evolving regulatory and economic challenges.

Condition Monitor empowers tank operators with accurate data and standardized documentation to ensure inspections and maintenance are efficient, safe and fully compliant.

centralized insight, faster decisions

By unifying asset condition data in one platform, teams gain a full view of each tank. Enabling quicker, smarter planning and action across all operations.

Maximize reliability and future-proof performance

With Condition Monitor, organizations can boost asset lifespan, optimize maintenance costs and stay ahead of evolving regulatory and economic challenges.

Overcoming outdated data

Overcoming outdated asset management

Tank storage facilities must maintain rigorous safety, operational, and compliance standards. But maintaining asset integrity is a complex challenge due to the unpredictable nature of corrosion, wear, and mechanical failure. Without a structured and consistent approach to asset monitoring, inefficiencies, safety hazards and costly maintenance issues can escalate quickly.

Inconsistent inspections and missed issues

Inspection practices often lack consistency, and monitoring intervals are hard to manage. Without standardized condition data, small problems go undetected until they become costly emergencies.

Corrosion risks and safety hazards

Harsh environments speed up corrosion, especially in critical areas like rim seals and tank bases. If not detected early, this can lead to structural failure, environmental harm and safety risks.

Fragmented data and decision-making challenges

Dispersed and siloed inspection data makes it hard to track issues or act promptly. Teams struggle with prioritization and timely decision-making.

The need for proactive monitoring

Regulatory demands, safety concerns, and high costs of reactive maintenance highlight the need for smarter, proactive Condition Monitoring strategies.

Inspection practices often lack consistency, and monitoring intervals are hard to manage. Without standardized condition data, small problems go undetected until they become costly emergencies.

Corrosion risks and safety hazards

Harsh environments speed up corrosion, especially in critical areas like rim seals and tank bases. If not detected early, this can lead to structural failure, environmental harm and safety risks.

Fragmented data and decision-making challenges

Dispersed and siloed inspection data makes it hard to track issues or act promptly. Teams struggle with prioritization and timely decision-making.

The need for proactive monitoring

Regulatory demands, safety concerns, and high costs of reactive maintenance highlight the need for smarter, proactive Condition Monitoring strategies.

A better way of working

A better way of working

To address the challenges faced by terminal operators, Falcker has developed Condition Monitor. This platform integrates multiple assessment methodologies, including visual inspections, NDT data management and tank property tracking: supporting audit compliance in standards such as API 653 and EEMUA 159.

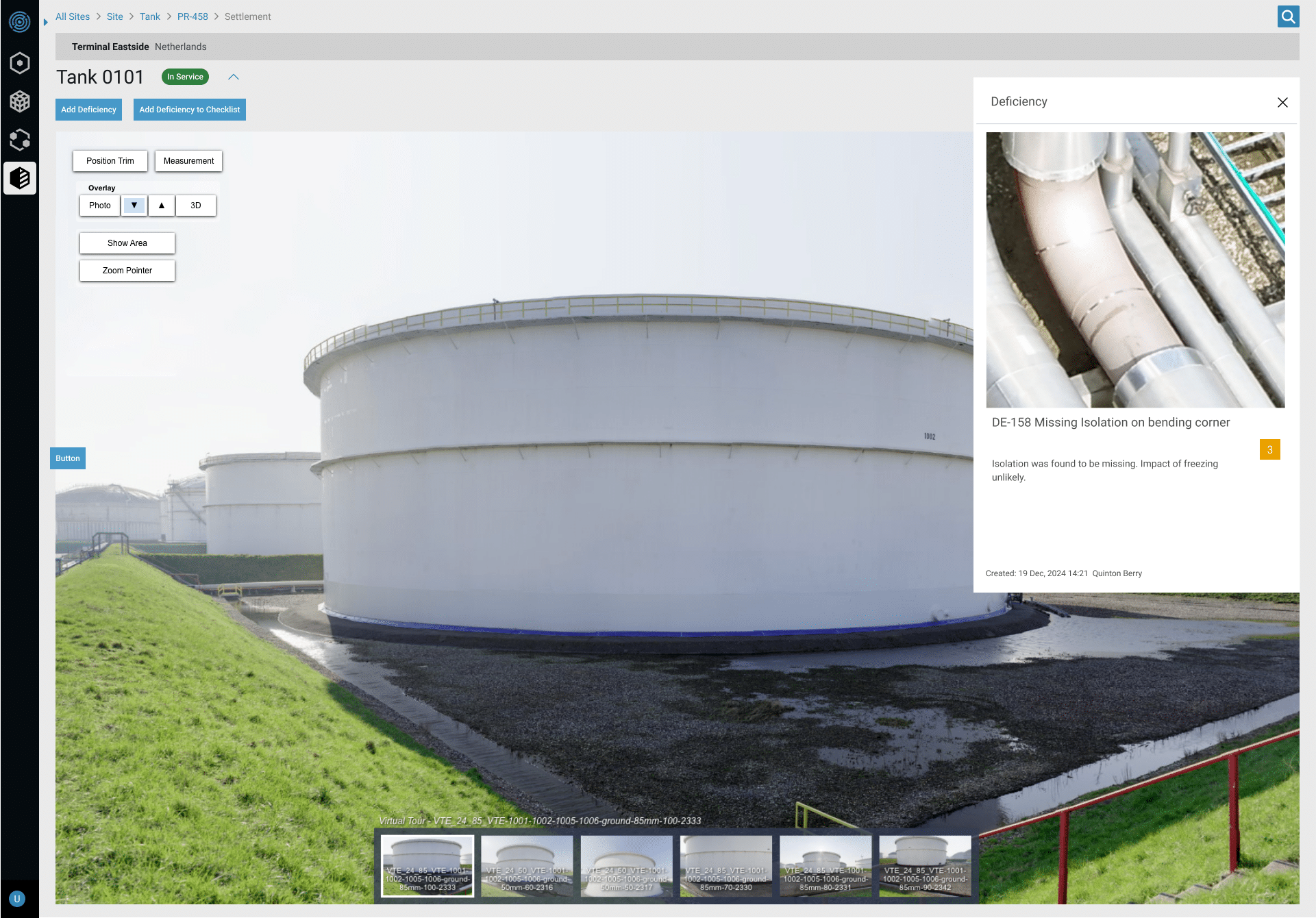

Standardization of visual inspections

Condition Monitor facilitates the standardization of visual inspections throughout the organization, assisting inspectors in identifying indicators of corrosion and mechanical failures early. With a centralized digital platform, Condition Monitor enables teams to access asset data, make informed decisions faster and collaborate efficiently to minimize downtime and maximize tank service life.

Operating to the highest standard

Information you can trust is so important in managing asset integrity from both a business and a compliance perspective. Having a clear breakdown of every asset’s history on top of an intelligent platform that can recommend repairs means your tanks can continue operating to the highest standard beyond their initial predicted lifespan.

Condition Monitor facilitates the standardization of visual inspections throughout the organization, assisting inspectors in identifying indicators of corrosion and mechanical failures early. With a centralized digital platform, Condition Monitor enables teams to access asset data, make informed decisions faster and collaborate efficiently to minimize downtime and maximize tank service life.

Operating to the highest standard

Information you can trust is so important in managing asset integrity from both a business and a compliance perspective. Having a clear breakdown of every asset’s history on top of an intelligent platform that can recommend repairs means your tanks can continue operating to the highest standard beyond their initial predicted lifespan.

Functionality

How does Condition Monitor work?

Condition Monitor integrates multiple assessment methodologies, including visual inspections, digital twin technology, NDT data management, tank property tracking and enhanced API 653 and EEMUA 159 assessments.

Automated Calculations

Condition Monitor automates settlement testing calculations and visualizations in line with API and EEMUA standards, enhanced with integrated cosine curve calculations.

Customizable Checklists

Easily update checklists to align with relevant regulations and specific requirements, ensuring all necessary data is captured during inspections and Fit For Service assessments.

Intelligent Repair Advice

The system provides automated, standardized repair scopes and timelines, supported by our Lifecycle Planner. It integrates NDT data to align actual and target lifespans with tailored repair recommendations.

Condition Monitor automates settlement testing calculations and visualizations in line with API and EEMUA standards, enhanced with integrated cosine curve calculations.

Customizable Checklists

Easily update checklists to align with relevant regulations and specific requirements, ensuring all necessary data is captured during inspections and Fit For Service assessments.

Intelligent Repair Advice

The system provides automated, standardized repair scopes and timelines, supported by our Lifecycle Planner. It integrates NDT data to align actual and target lifespans with tailored repair recommendations.

Features & Benefits

Accurate monitoring of tank integrity

Predictive analytics to prevent costly failures

Digital documentation for streamlined compliance and auditing

Reduced reliance on manual inspections

3D model visualization of tank components with inspection data integration

Deployment

How is Condition Monitor deployed?

We are committed to a streamlined and standardized delivery process when it comes to onboarding a new Condition Monitor customer.

1

Kick-off

We begin with a structured kick-off, aligning stakeholders and goals to ensure a smooth fit between your needs and our solutions. A user list is created early to engage key team members from the outset.

2

Data onboarding

Your existing data is collected and imported into Condition Monitor. We help tailor documentation to meet your inspection and compliance needs. Ready to go from day one.

3

Hands-on training

Key users are involved early, with training that covers system navigation, logins, and real-world applications. This ensures Condition Monitor becomes part of everyday operations.

4

Ongoing support

We don’t stop at launch. We provide continuous support, monitor usage, gather feedback, and evolves the system to meet your growing needs. Ensuring long-term value and future readiness.

Reach out to our team of experts.

Get in touch with our team directly.

+31 10 307 13 50Or send an email to

info@falcker.comFind the right solution for you