Early issue detection for sustainable and safe operations.

Falcker’s Operator Round solution addresses operator’s challenges by automating routine operator tasks while ensuring compliance.

What’s the impact?

What Impact can Operator Round have?

At Falcker, we focus on delivering tangible operational benefits.

Features & Benefits

Reduced operational downtime by spotting asset issues early

Lower repair costs on all tanks as repair issues are detected before they escalate

Optimal safety and compliance on-site

Real-time access to accurate information

With Operator Round, tank operators can confidently maintain efficient, safe, and compliant operations. The centralized digital platform provides real-time access to accurate information that helps teams spot issues earlier, and put cost-effective fixes in place, ensuring extended asset life, continued compliance, and a safer working environment for all.

Future-proof operations

By digitizing and optimizing operational processes, teams can make faster, more informed decisions while enhancing project planning and repair execution. Operator Round empowers organizations to maximize process reliability, optimize repair spending by doing work as soon as it’s needed, and future-proof operations in an increasingly complex regulatory and economic landscape.

With Operator Round, tank operators can confidently maintain efficient, safe, and compliant operations. The centralized digital platform provides real-time access to accurate information that helps teams spot issues earlier, and put cost-effective fixes in place, ensuring extended asset life, continued compliance, and a safer working environment for all.

Future-proof operations

By digitizing and optimizing operational processes, teams can make faster, more informed decisions while enhancing project planning and repair execution. Operator Round empowers organizations to maximize process reliability, optimize repair spending by doing work as soon as it’s needed, and future-proof operations in an increasingly complex regulatory and economic landscape.

Critical challenges

The operational challenges facing operators

Tank storage facilities rely on frequent checkups to ensure safety, operational continuity, and regulatory compliance. But traditional practices are often inconsistent, inefficient, and prone to human error. Without a structured and reliable approach, small issues can go unnoticed, escalating into costly failures and unplanned downtime.

Why consistent monitoring matters

One of the primary challenges in tank maintenance is ensuring regular monitoring. Without systematic checks, critical issues can go unnoticed. Leading to environmental pollution, lost capital, safety hazards, and higher repair costs. These inspections often require accessing tall tanks and working at height, sometimes in adverse weather, which adds significant safety risk.

Risks that can’t wait

Tank operators face serious threats like fires from rim seal failures and leaks from corrosion. When detection is delayed, due to irregular rounds or poor maintenance, hazardous conditions can develop, putting people and the environment at risk. This also impacts uptime and damages customer trust.

One of the primary challenges in tank maintenance is ensuring regular monitoring. Without systematic checks, critical issues can go unnoticed. Leading to environmental pollution, lost capital, safety hazards, and higher repair costs. These inspections often require accessing tall tanks and working at height, sometimes in adverse weather, which adds significant safety risk.

Risks that can’t wait

Tank operators face serious threats like fires from rim seal failures and leaks from corrosion. When detection is delayed, due to irregular rounds or poor maintenance, hazardous conditions can develop, putting people and the environment at risk. This also impacts uptime and damages customer trust.

Work smarter, not harder

Work smarter, not harder

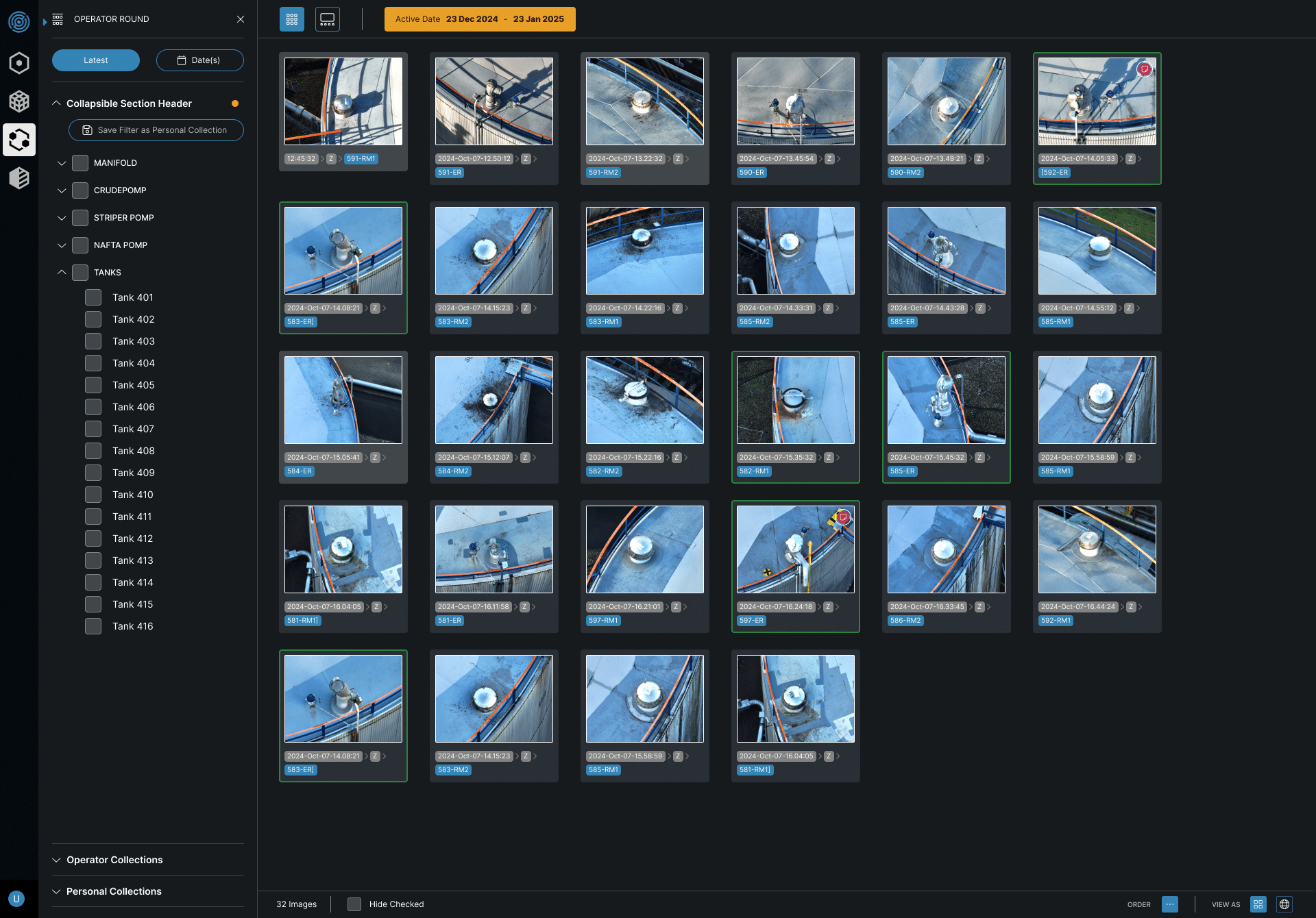

Operator Round is a tool that enables users to efficiently carry out their operator rounds and planning by making them digital. With advanced drone technology capturing high-resolution photos on every flight and with each image in Operator Round featuring essential contextual details, such as the specific location, tag and timestamp, operators can always get a comprehensive and up-to-date understanding of site and asset conditions.

Real-time, consistent inspections

A drone box installed on-site allows terminal operators to manage drones directly from the facility. Using automated flight paths or manual control during emergencies. Through a centralized digital platform, Operator Round enables real-time, consistent inspections that follow a structured process. This supports early detection of issues like containment loss, drainage failures, or floating roof concerns.

Documenting and analyzing tank conditions

Operator Round replaces paper-based checks with a smart, guided system for documenting and analyzing tank conditions. This shift enhances efficiency, reduces risk, minimizes disruptions, and helps ensure optimal asset performance.

A drone box installed on-site allows terminal operators to manage drones directly from the facility. Using automated flight paths or manual control during emergencies. Through a centralized digital platform, Operator Round enables real-time, consistent inspections that follow a structured process. This supports early detection of issues like containment loss, drainage failures, or floating roof concerns.

Documenting and analyzing tank conditions

Operator Round replaces paper-based checks with a smart, guided system for documenting and analyzing tank conditions. This shift enhances efficiency, reduces risk, minimizes disruptions, and helps ensure optimal asset performance.

Functionality

How does Operator Round work?

Operator Round uses automated drone flights and image capture to deliver a regular stream of asset data; giving operations teams a clear picture of the condition and unexpected failures or leakages of every tank they have to monitor.

HD Imagery For Every Asset

One of Operator Round’s key features is its consistent photo-taking method. Capturing images from the same position and angle allows easy comparison over time to detect wear, degradation, or other changes. If issues are found, users can mark them directly on the image for clear visibility to all team members.

Total Traceability

The system logs all image interactions, creating a complete audit trail to ensure photos are reviewed and approved, boosting accountability and operational effectiveness.

Search Everywhere, Find Everything

Operator Round’s image gallery offers seamless navigation by date or tag. Users can apply retroactive tags to photos for better organization and retrieval, and the timeline functionality allows easy tracking of asset and component evolution over time.

One of Operator Round’s key features is its consistent photo-taking method. Capturing images from the same position and angle allows easy comparison over time to detect wear, degradation, or other changes. If issues are found, users can mark them directly on the image for clear visibility to all team members.

Total Traceability

The system logs all image interactions, creating a complete audit trail to ensure photos are reviewed and approved, boosting accountability and operational effectiveness.

Search Everywhere, Find Everything

Operator Round’s image gallery offers seamless navigation by date or tag. Users can apply retroactive tags to photos for better organization and retrieval, and the timeline functionality allows easy tracking of asset and component evolution over time.

Features & Benefits

Accurate and up-to-date site-wide asset imagery

Early detection of operating issues

Operational issue tracking for all users as standard

The means to plan repairs before an issue gets worse

Deployment

How is Operator Round deployed?

We are committed to a streamlined and standardized delivery process when it comes to onboarding a new Operator Round customer.

1

Kick-off phase

We begin with a structured kick-off, aligning stakeholders and ensuring your goals align with our solutions. A user list is created early, and flight permits are secured alongside a Job Safety Analysis (JSA) for compliance.

2

Drone Box installation

Next, we install the drone box in an optimal location, minimizing flight risks like ATEX zones and optimizing flight paths for efficient data collection.

3

Launch and training

The launch phase includes training key employees on navigation, login, and practical use cases, ensuring smooth adoption of the system and embedding Operator Round into daily operations for better decision-making.

4

Ongoing support

We ensure long-term value through continuous follow-up, monitoring usage, gathering feedback, and expanding use cases to keep Operator Round evolving and integral to your operations.

Reach out to our team of experts.

Get in touch with our team directly.

+31 10 307 13 50Or send an email to

info@falcker.comFind the right solution for you