A bird’s eye view of your storage tank terminals.

The Site Explorer platform provides a cloud-based intuitive digital user experience; powered by advanced mapping software and UAV/drone technology.

What’s the impact?

What impact can Site Explorer have?

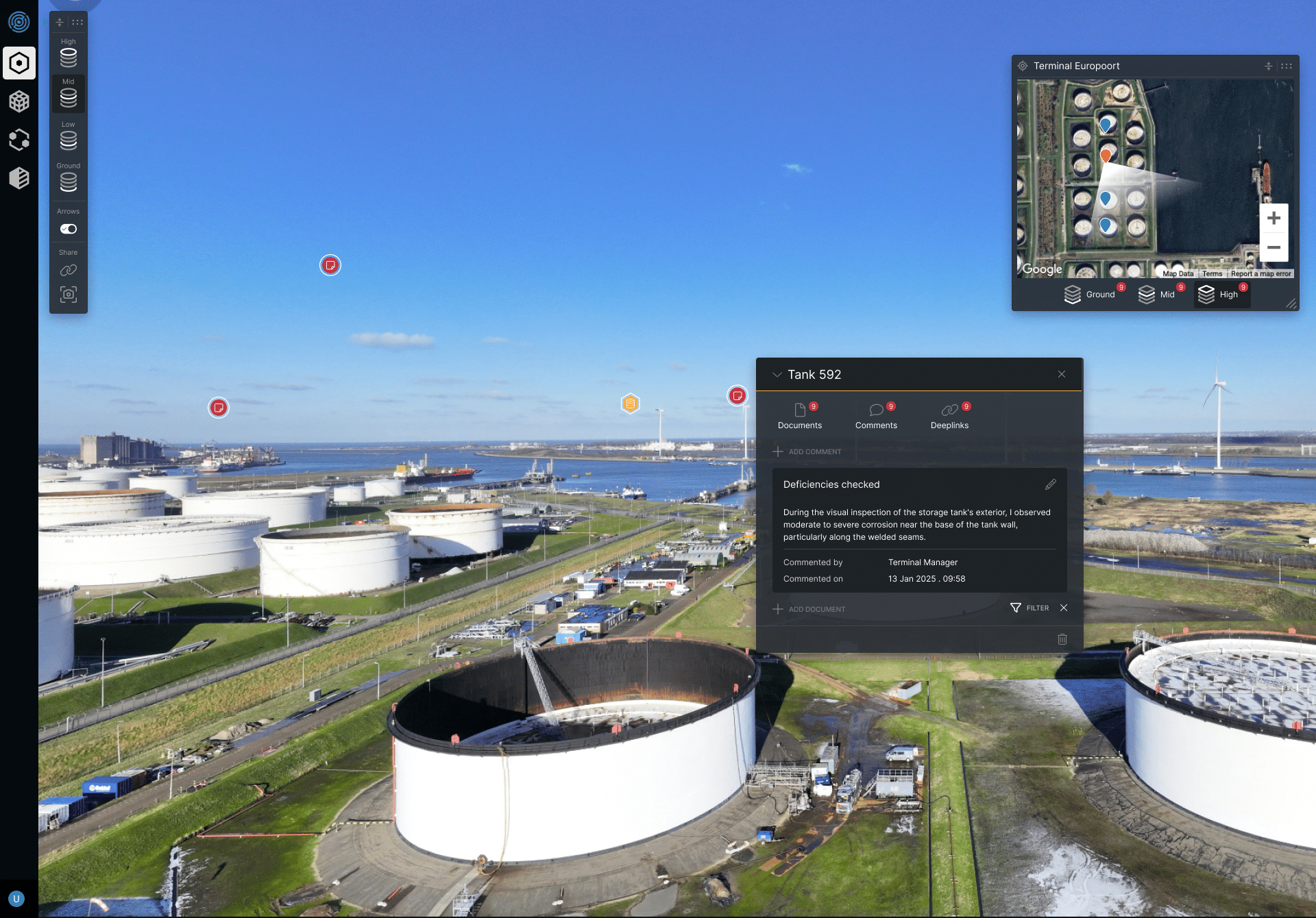

Within the platform itself assets, equipment or pipelines can be tagged. This allows users to easily locate the relevant asset location. Every asset can be accompanied by documents, comments or links to other systems.

Features & Benefits

Benefit from large increases in operational efficiency

Create a safer working environment for everyone

Get a 360° birds-eye-view of your entire terminal

Collaborate more effectively with internal and external parties

Access and sharing

Site Explorer links direct users to specific on-site locations or external systems like Maintenance Management Systems, streamlining information access and sharing.

Remote-accessible overview

By centralizing visual and technical asset data online, all stakeholders, internal and external, gain a complete, remote-accessible overview of the facility.

Simplifying collaboration

This enables better collaboration, detailed planning, and more accurate quotes from subcontractors. Internally, Site Explorer minimizes the need for repeated terminal visits. Photos and data can be easily accessed during meetings or planning sessions, simplifying collaboration. Especially with off-site or international teams.

Site Explorer links direct users to specific on-site locations or external systems like Maintenance Management Systems, streamlining information access and sharing.

Remote-accessible overview

By centralizing visual and technical asset data online, all stakeholders, internal and external, gain a complete, remote-accessible overview of the facility.

Simplifying collaboration

This enables better collaboration, detailed planning, and more accurate quotes from subcontractors. Internally, Site Explorer minimizes the need for repeated terminal visits. Photos and data can be easily accessed during meetings or planning sessions, simplifying collaboration. Especially with off-site or international teams.

Critical challenges

The critical challenges facing tank operators

Tank terminal operations are inherently complex. Requiring coordination, skilled personnel, and efficient workflows to ensure safety, cost-effectiveness and regulatory compliance. However, there are universal challenges that continue to hinder operational efficiency and increase risks for all operators.

Tank terminal operations face critical challenges, including inefficient maintenance that increases downtime, costs, and safety risk issues made worse by a shortage of skilled personnel. Communication hurdles across different locations and time zones often lead to miscommunication and incomplete project scoping. In addition, poor contractor coordination elevates on-site safety risks and results in misaligned risk assessments due to overcrowding. Cost control is undermined by unforeseen expenses and scattered documentation, which frequently cause errors and inefficiencies.

To manage these complex, interdependent activities within tight budgets, a streamlined, collaborative approach is essential.

To manage these complex, interdependent activities within tight budgets, a streamlined, collaborative approach is essential.

Innovative change needed

The innovative change needed

These challenges highlight the urgent need for a comprehensive digital solution that optimizes resource allocation, enhances communication and digitizes key workflows.

Intuitive digital user experience

Powered by advanced mapping software and UAV/drone technology, Site Explorer provides a cloud-based intuitive digital user experience. This allows tank operators to optimize procurement, minimize risks, and improve operational efficiency – making work preparation safer, faster, and more cost-effective.

Improve safety and productivity

Site Explorer also helps to improve safety and productivity by providing digital access to built environment information, both improving situational awareness and remote collaboration, while reducing reliance on multiple contractors for inspections.

Connect the dots to gather insight

Connected information is key because asset visuals and technical information are made available online within a single platform. With so much data already available within every tank operator’s business, Site Explorer helps your people connect the dots to gather insight and share understanding faster than ever before.

Powered by advanced mapping software and UAV/drone technology, Site Explorer provides a cloud-based intuitive digital user experience. This allows tank operators to optimize procurement, minimize risks, and improve operational efficiency – making work preparation safer, faster, and more cost-effective.

Improve safety and productivity

Site Explorer also helps to improve safety and productivity by providing digital access to built environment information, both improving situational awareness and remote collaboration, while reducing reliance on multiple contractors for inspections.

Connect the dots to gather insight

Connected information is key because asset visuals and technical information are made available online within a single platform. With so much data already available within every tank operator’s business, Site Explorer helps your people connect the dots to gather insight and share understanding faster than ever before.

Functionality

How does Site Explorer work?

Site Explorer offers an intuitive user experience that visualizes site-wide assets. In this way, we help tank operators eliminate inefficiencies in their tank management by providing accurate, infrastructure data: on demand.

360˚ Bird’s Eye View

Thanks to state-of-the-art drone technology, Site Explorer’s intuitive platform gives refinery operators a bird’s eye view of their storage tank facilities in situ. This enables users to navigate multiple site locations using high-resolution 360° aerial images, zooming in for detail and selecting capture points on a 2D map.

Asset Tagging

Within Site Explorer, any asset, piece of equipment, or pipeline can be tagged inside each 360° image. This allows users to easily search for the relevant image locations aligned with each tagged term, before they’re automatically served the corresponding map image.

Connected Information

Because asset visuals and technical information are made available online with Site Explorer, all users, and operators involved in the maintenance process can access on-demand insights and have a complete overview of their storage tank facilities. This means they can collaborate even more efficiently, while also reducing the need for physical presence on-site.

Thanks to state-of-the-art drone technology, Site Explorer’s intuitive platform gives refinery operators a bird’s eye view of their storage tank facilities in situ. This enables users to navigate multiple site locations using high-resolution 360° aerial images, zooming in for detail and selecting capture points on a 2D map.

Asset Tagging

Within Site Explorer, any asset, piece of equipment, or pipeline can be tagged inside each 360° image. This allows users to easily search for the relevant image locations aligned with each tagged term, before they’re automatically served the corresponding map image.

Connected Information

Because asset visuals and technical information are made available online with Site Explorer, all users, and operators involved in the maintenance process can access on-demand insights and have a complete overview of their storage tank facilities. This means they can collaborate even more efficiently, while also reducing the need for physical presence on-site.

Features & Benefits

Site-wide insight for every operator

Safe and efficient drone-based data capture

Easy-to-navigate visual information

High-resolution 360° images

Powerful navigation and search tools

Role-based user access for external contractors

Great first step in wider asset digitization

Implementation

The critical challenges facing tank operators

Tank terminal operations are inherently complex. Requiring coordination, skilled personnel, and efficient workflows to ensure safety, cost-effectiveness, and regulatory compliance. However, there are universal challenges that continue to hinder operational efficiency and increase risks for all operators.

1

Kick-off

We begin with a structured kick-off: aligning stakeholders, securing permits, and ensuring safety with a Job Safety Analysis. Key personnel gain early access, and a tailored flight plan sets the stage.

2

Capturing of imagery

Next, drones capture high-res imagery at 50m and 100m, producing interactive site maps with five 360° images per hectare. Multiple drones ensure continuous, efficient data collection.

3

Key staff training

In the launch phase, we train key staff on navigation, login, and real-world use cases, integrating Site Explorer into daily operations for smarter, data-driven decisions.

4

Ongoing support

We add lasting value through ongoing support-monitoring usage, collecting feedback, and expanding tailored use cases, ensuring Site Explorer evolves with your needs.

Reach out to our team of experts.

Get in touch with our team directly.

+31 10 307 13 50Or send an email to

info@falcker.comFind the right solution for you