The benefits of bringing intelligence to your storage tank portfolio

In response to challenges terminal owners face, we continue to offer secure, cloud-based inspection and maintenance software. These digital workflow solutions address all the above challenges while deploying technologies such as digital twinning, artificial intelligence and inspection data management.

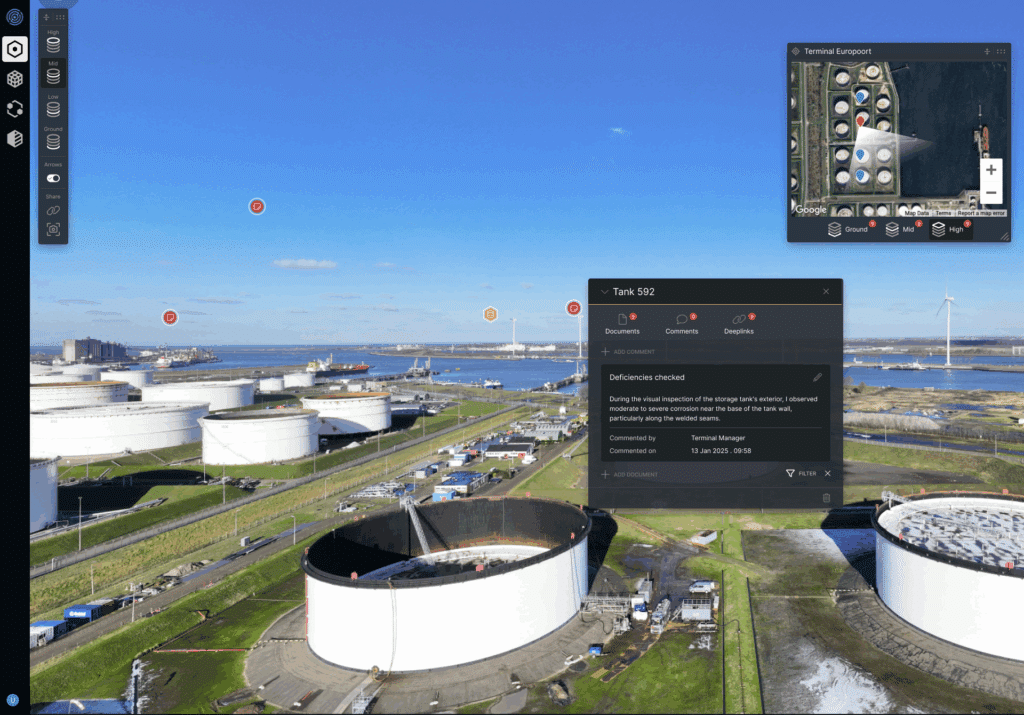

A bird’s eye view of your storage tank terminals

Tank terminal operations are inherently complex – requiring coordination, skilled personnel, and efficient workflows to ensure safety, cost-effectiveness, and regulatory compliance. However, there are universal challenges that continue to hinder operational efficiency and increase risks for all operators.

Tank terminal operations are inherently complex – requiring coordination, skilled personnel, and efficient workflows to ensure safety, cost-effectiveness, and regulatory compliance. However, there are universal challenges that continue to hinder operational efficiency and increase risks for all operators.

Features & Benefits

- Easy-to-navigate visual information

- High resolution 360˚ images

- Powerful navigation and search tools

- Efficient and safe drone-based data acquisition

- Roles-based software access for external contractors

- Complete operator insight and overview

John Bruijnooge

Manufacturing Executive, SABIC

“Digitization needs to add value; contribute to long-term objectives; and enable collaboration, safety, and efficiency. We have definitely made the right choice with Falcker and Site Explorer’’

SABIC Geleen is a leading player in the chemical industry, located in the south of the Netherlands.

The company operates its production facility at Geleen’s Chemelot Industrial Park: an enormous area, where numerous companies operate. The sheer size of the park and the complexity of operating in shared spaces can make it challenging for operators and contractors to locate the right pipelines, equipment, and storage tanks for inspection and maintenance. But that’s no longer the case, thanks to Falcker’s Site Explorer platform.

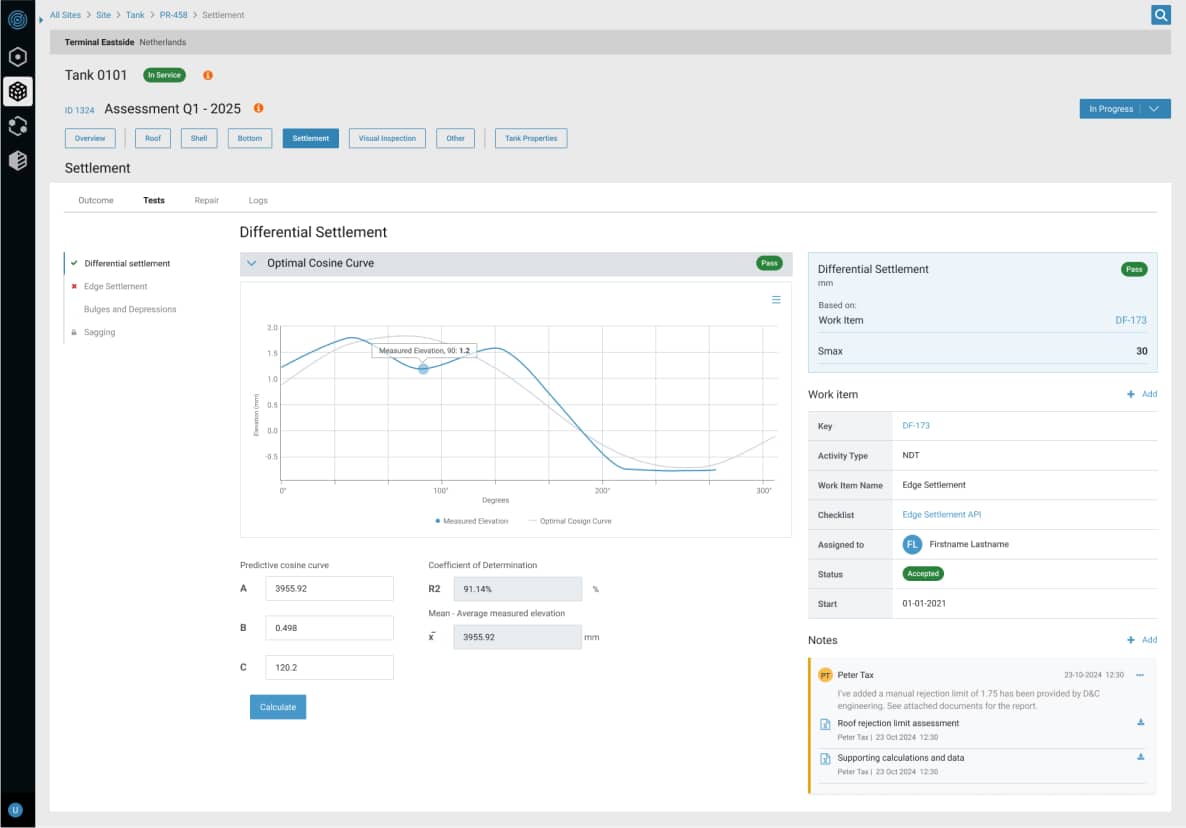

Improve inspections, maintenance, and compliance

Tank storage facilities must maintain rigorous safety, operational, and compliance standards. But maintaining asset integrity is a complex challenge due to the unpredictable nature of corrosion, wear, and mechanical failure. Without a structured and consistent approach to asset monitoring, inefficiencies, safety hazards, and costly maintenance issues can escalate quickly.

With increasing regulatory pressure, safety concerns, and the financial burden of reactive maintenance, tank operators need a smarter, more proactive approach to asset condition monitoring.

Tank storage facilities must maintain rigorous safety, operational, and compliance standards. But maintaining asset integrity is a complex challenge due to the unpredictable nature of corrosion, wear, and mechanical failure. Without a structured and consistent approach to asset monitoring, inefficiencies, safety hazards and costly maintenance issues can escalate quickly.

With increasing regulatory pressure, safety concerns, and the financial burden of reactive maintenance, tank operators need a smarter, more proactive approach to asset condition monitoring.

Features & Benefits

- Intuitive 3D digital twinning

- A complete repository of assets and properties

- Potential for remote offsite assessment

- Statistical analysis

- Compliant assessment and reporting

- Document upload, search, and storage

- Asset search and location map

- Enables both time-based and risk-based inspections

- Fully-automated PED, API 653 and EEMUA 159 fit-for-service assessments

- Automated drone flights provide visual, geometrical, and gas emission inspections

Hans Looij

Operations Excellence Superintendent, BP Refinery Rotterdam

“Falcker has provided Condition Monitoring software and automated drone data and analysis for BP Rotterdam for several years. The platform has significantly improved compliance, control, and insights for the team. An inspection contractor also uses the platform remotely to make mandatory EEMUA 159 and PGS-29 assessments.”

BP is a global leader in processing crude oil and one of the largest oil refineries in Europe. The company is located in Europoort, Rotterdam, processing 400,000 barrels of crude oil per day.

The global maintenance team has worked with Falcker to build best practices and now has a greater understanding of asset management practices. This has empowered Falcker to create digital solutions that improve asset integrity and lifecycle planning for storage tank owners globally.

The global maintenance team has worked with Falcker to build best practices and now has a greater understanding of asset management practices. This has empowered Falcker to create digital solutions that improve asset integrity and lifecycle planning for storage tank owners globally.

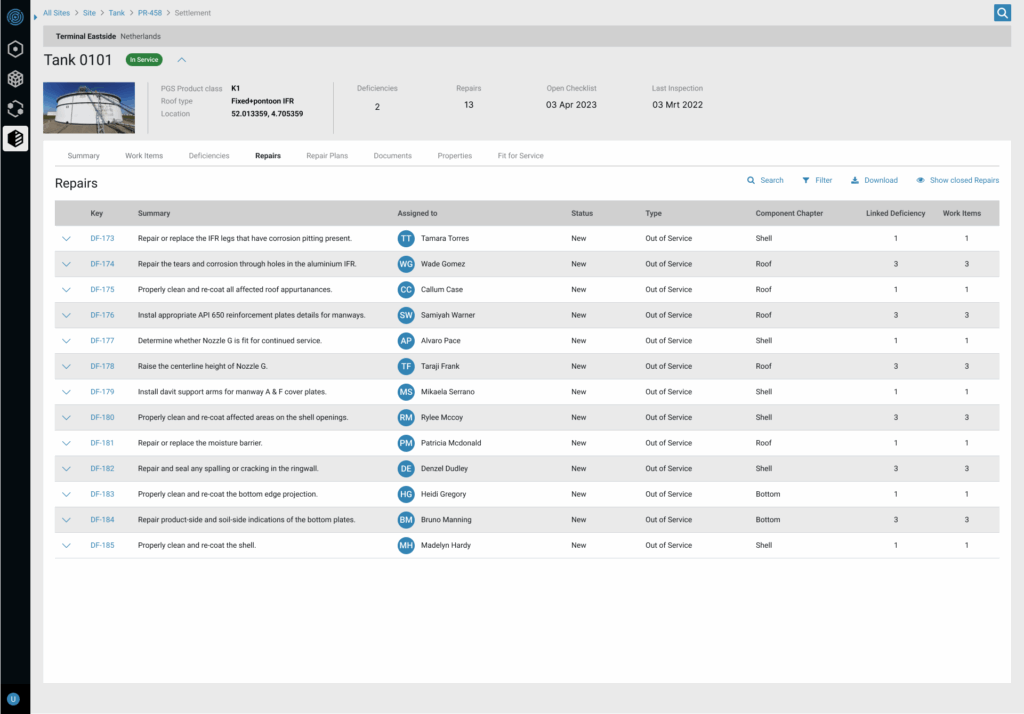

Capital preservation & asset utilization in maintenance

As storage and pipeline systems age, the need for proactive planning becomes critical. Tank terminal operators face growing complexity in managing their assets efficiently while maintaining long-term reliability. Key responsibilities include scheduling maintenance, planning inspections, and addressing aging infrastructure.

As storage and pipeline systems age, the need for proactive planning becomes critical. Tank terminal operators face growing complexity in managing their assets efficiently while maintaining long-term reliability. Key responsibilities include scheduling maintenance, planning inspections, and addressing aging infrastructure.

Features & Benefits

- Improved pre-scoping and budgeting

- Prioritization of urgent asset integrity issues

- Understand wider market best practices

- Maximize the value of existing repair history and maintenance cost data

Timo Spaniks

President Vopak Belgium

“The goal of our work together has been to capture as much value as possible and we do this by co-creating with Falcker. We believe that innovation is key to maintaining Vopak’s critical asset infrastructure and I foresee unlimited possibilities in the long-term working with Falcker.’’

Vopak is a global leader in tank storage, providing storage solutions for chemicals, oils, gases, and biofuels, supporting industries and supply chains worldwide.

The global maintenance team has worked with Falcker to build best practices and now has a greater understanding of asset management practices. This has empowered Falcker to create digital solutions that improve asset integrity and lifecycle planning for storage tank owners globally.

The global maintenance team has worked with Falcker to build best practices and now has a greater understanding of asset management practices. This has empowered Falcker to create digital solutions that improve asset integrity and lifecycle planning for storage tank owners globally.

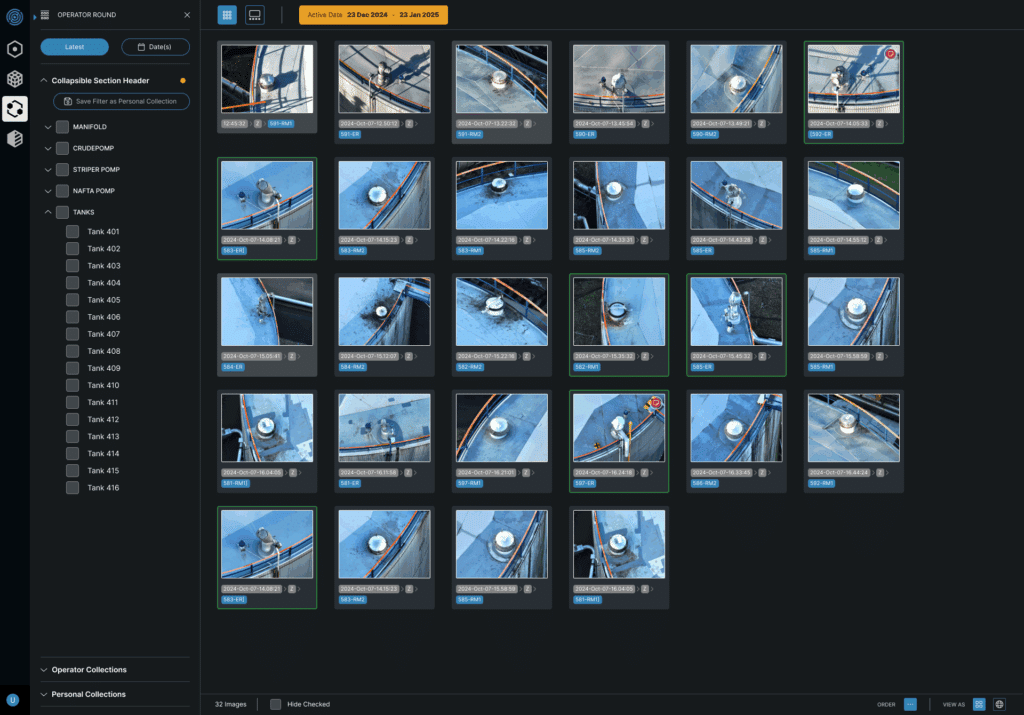

Early issue detection for sustainable and safe operations

Tank storage facilities rely on frequent checkups to ensure safety, operational continuity, and regulatory compliance. But traditional practices are often inconsistent, inefficient, and prone to human error. Without a structured and reliable approach, small issues can go unnoticed, escalating into costly failures and unplanned downtime.

A streamlined, collaborative approach to tank terminal management is essential, but best practices require addressing a wide range of interwoven operational activity, as well as lean budgets.

Tank storage facilities rely on frequent checkups to ensure safety, operational continuity, and regulatory compliance. But traditional practices are often inconsistent, inefficient, and prone to human error. Without a structured and reliable approach, small issues can go unnoticed, escalating into costly failures and unplanned downtime.

A streamlined, collaborative approach to tank terminal management is essential, but best practices require addressing a wide range of interwoven operational activities, as well as lean budgets.

Features & Benefits

- ATEX-compliant flight procedures

- 24/7 availability on-site

- Pre-programmed inspection rounds

- Drone operation by terminal operators

- Reduction of working at height

- Centralized activity in the control room

- Audit trail for all photos

Kees Bevaart

Terminal Manager, Maasvlakte Oil Terminal

“Falcker proves drone technology can finally be utilized safely by terminal operators and within ATEX directives. It has been a huge driver of efficiencies for our operators.”

The Maasvlakte Oil Terminal (MOT) is a large crude feedstock terminal and the entrance into the Port of Rotterdam; supplying Vopak, Exxon, BP, Shell, Aramco, and Total.

The MOT has been working with Falcker since 2018 and has laid the foundation for many of the solutions we offer today. Working closely with an operator has accelerated the development of intelligent solutions that tackle the challenges of the storage tanks industry.

The MOT has been working with Falcker since 2018 and has laid the foundation for many of the solutions we offer today. Working closely with an operator has accelerated the development of intelligent solutions that tackle the challenges of the storage tanks industry.

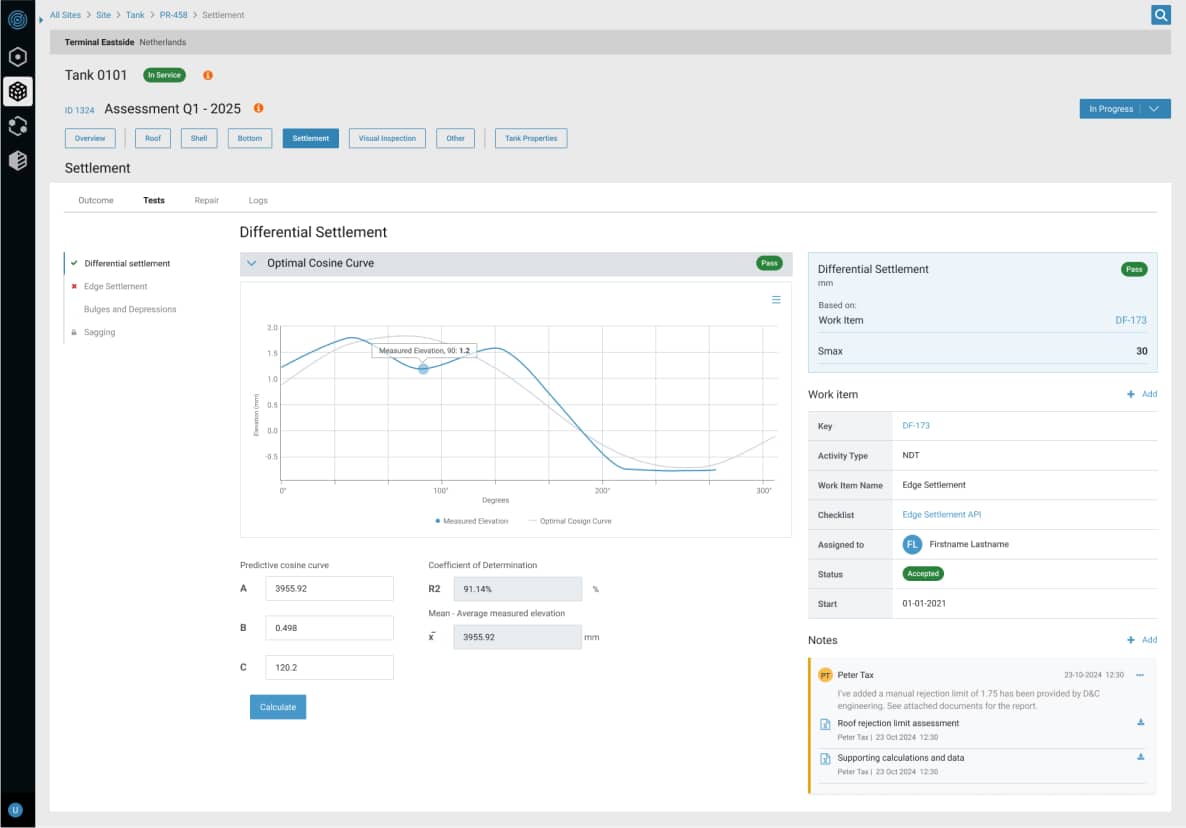

Condition Monitor

Improve inspections, maintenance, and compliance

Tank storage facilities must maintain rigorous safety, operational, and compliance standards. But maintaining asset integrity is a complex challenge due to the unpredictable nature of corrosion, wear, and mechanical failure. Without a structured and consistent approach to asset monitoring, inefficiencies, safety hazards, and costly maintenance issues can escalate quickly.

With increasing regulatory pressure, safety concerns, and the financial burden of reactive maintenance, tank operators need a smarter, more proactive approach to asset condition monitoring.

Features & Benefits

- Intuitive 3D digital twinning

- A complete repository of assets and properties

- Potential for remote offsite assessment

- Statistical analysis

- Compliant assessment and reporting

- Document upload, search, and storage

- Asset search and location map

- Enables both time-based and risk-based inspections

- Fully-automated PED, API 653 and EEMUA 159 fit-for-service assessments

- Automated drone flights provide visual, geometrical, and gas emission inspections

“Falcker has provided Condition Monitoring software and automated drone data and analysis for BP Rotterdam for several years. The platform has significantly improved compliance, control, and insights for the team. An inspection contractor also uses the platform remotely to make mandatory EEMUA 159 and PGS-29 assessments.”

Hans Looij

Operations Excellence Superintendent, BP Refinery Rotterdam

BP is a global leader in processing crude oil and one of the largest oil refineries in Europe. The company is located in Europoort, Rotterdam, processing 400,000 barrels of crude oil per day.

The global maintenance team has worked with Falcker to build best practices and now has a greater understanding of asset management practices. This has empowered Falcker to create digital solutions that improve asset integrity and lifecycle planning for storage tank owners globally.

The global maintenance team has worked with Falcker to build best practices and now has a greater understanding of asset management practices. This has empowered Falcker to create digital solutions that improve asset integrity and lifecycle planning for storage tank owners globally.

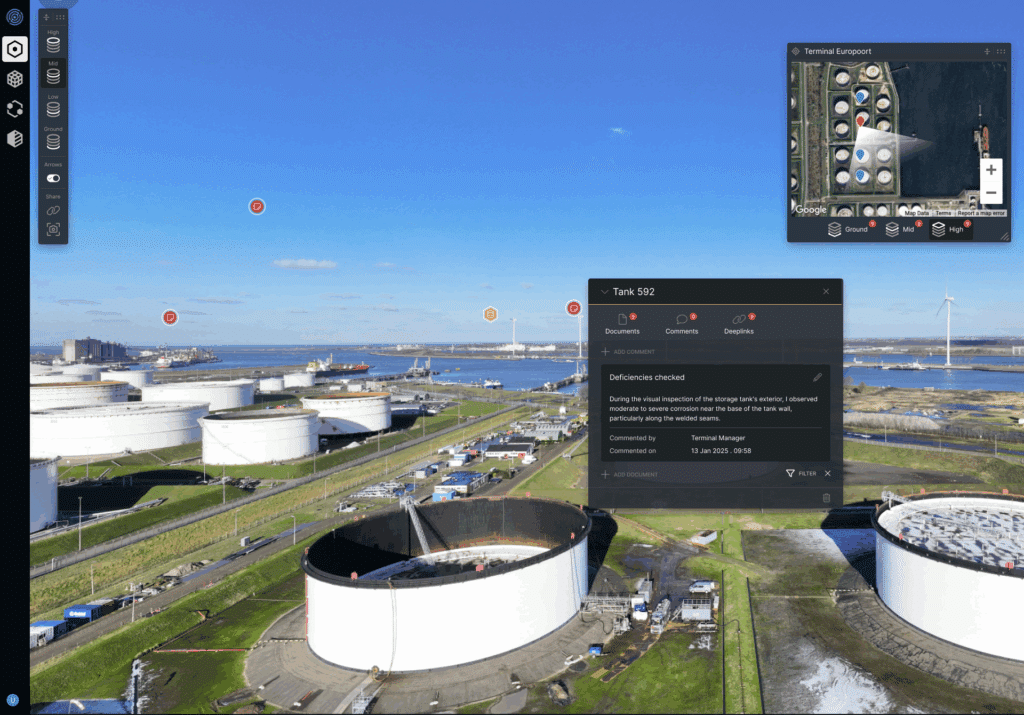

A bird’s eye view of your storage tank terminals

Tank terminal operations are inherently complex – requiring coordination, skilled personnel, and efficient workflows to ensure safety, cost-effectiveness, and regulatory compliance. However, there are universal challenges that continue to hinder operational efficiency and increase risks for all operators.

Features & Benefits

- Easy-to-navigate visual information

- High resolution 360˚ images

- Powerful navigation and search tools

- Efficient and safe drone-based data acquisition

- Roles-based software access for external contractors

- Complete operator insight and overview

“Digitization needs to add value; contribute to long-term objectives; and enable collaboration, safety, and efficiency. We have definitely made the right choice with Falcker and Site Explorer’’

John Bruijnooge

Manufacturing Executive, SABIC

SABIC Geleen is a leading player in the chemical industry, located in the south of the Netherlands.

The company operates its production facility at Geleen’s Chemelot Industrial Park: an enormous area, where numerous companies operate. The sheer size of the park and the complexity of operating in shared spaces can make it challenging for operators and contractors to locate the right pipelines, equipment, and storage tanks for inspection and maintenance. But that’s no longer the case, thanks to Falcker’s Site Explorer platform.

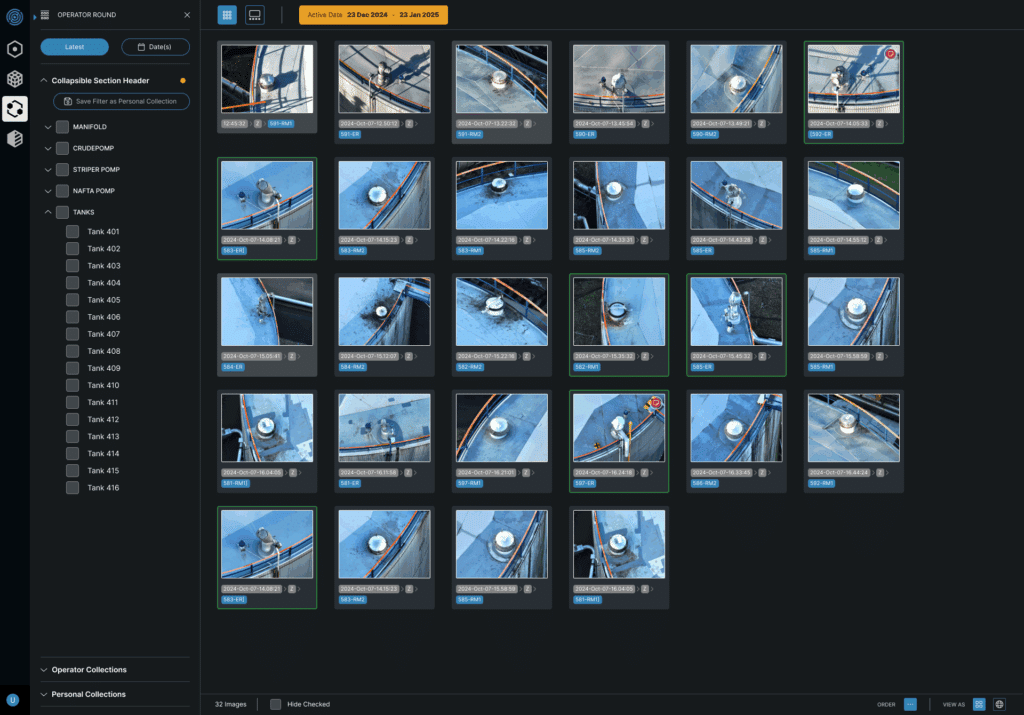

Operator Round

Early issue detection for sustainable and safe operations

Tank storage facilities rely on frequent checkups to ensure safety, operational continuity, and regulatory compliance. But traditional practices are often inconsistent, inefficient, and prone to human error. Without a structured and reliable approach, small issues can go unnoticed, escalating into costly failures and unplanned downtime.

A streamlined, collaborative approach to tank terminal management is essential, but best practices require addressing a wide range of interwoven operational activity, as well as lean budgets.

Features & Benefits

- ATEX-compliant flight procedures

- 24/7 availability on-site

- Pre-programmed inspection rounds

- Drone operation by terminal operators

- Reduction of working at height

- Centralized activity in the control room

- Audit trail for all photos

“Falcker proves drone technology can finally be utilized safely by terminal operators and within ATEX directives. It has been a huge driver of efficiencies for our operators.”

Kees Bevaart

Terminal Manager, Maasvlakte Oil Terminal

The Maasvlakte Oil Terminal (MOT) is a large crude feedstock terminal and the entrance into the Port of Rotterdam; supplying Vopak, Exxon, BP, Shell, Aramco, and Total.

The MOT has been working with Falcker since 2018 and has laid the foundation for many of the solutions we offer today. Working closely with an operator has accelerated the development of intelligent solutions that tackle the challenges of the storage tanks industry.

The MOT has been working with Falcker since 2018 and has laid the foundation for many of the solutions we offer today. Working closely with an operator has accelerated the development of intelligent solutions that tackle the challenges of the storage tanks industry.

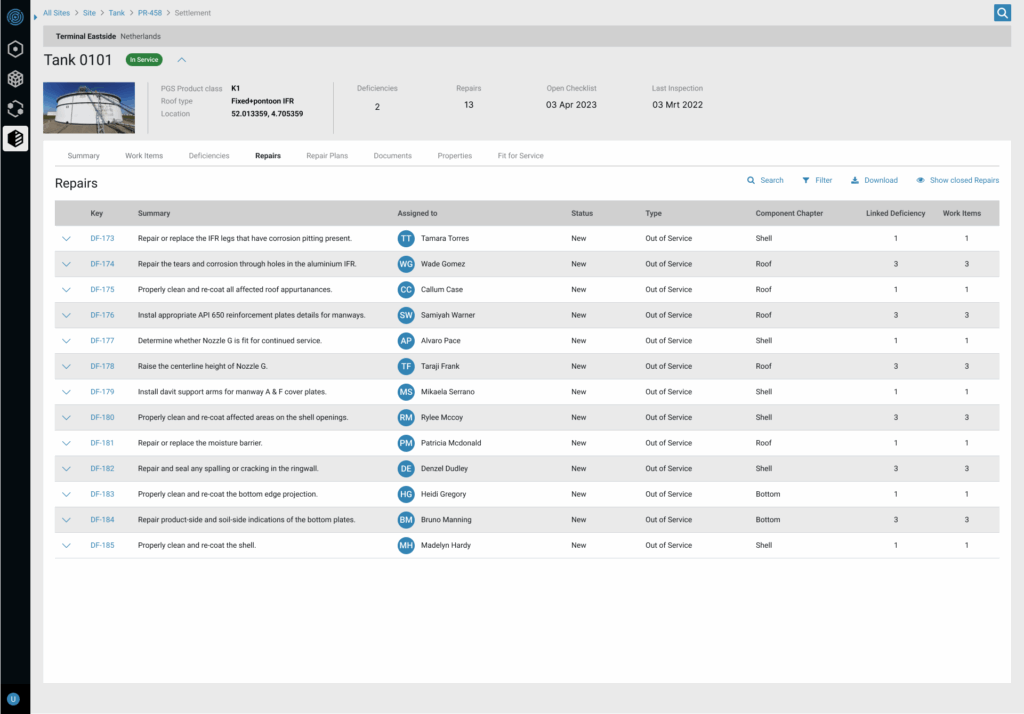

Lifecycle Planner

Capital preservation & asset utilization in maintenance

As storage and pipeline systems age, the need for proactive planning becomes critical. Tank terminal operators face growing complexity in managing their assets efficiently while maintaining long-term reliability. Key responsibilities include scheduling maintenance, planning inspections, and addressing aging infrastructure.

Features & Benefits

- Improved pre-scoping and budgeting

- Prioritization of urgent asset integrity issues

- Understand wider market best practices

- Maximize the value of existing repair history and maintenance cost data

“The goal of our work together has been to capture as much value as possible and we do this by co-creating with Falcker. We believe that innovation is key to maintaining Vopak’s critical asset infrastructure and I foresee unlimited possibilities in the long-term working with Falcker.’’

Timo Spaniks

President Vopak Belgium

Vopak is a global leader in tank storage, providing storage solutions for chemicals, oils, gases, and biofuels, supporting industries and supply chains worldwide.

The global maintenance team has worked with Falcker to build best practices and now has a greater understanding of asset management practices. This has empowered Falcker to create digital solutions that improve asset integrity and lifecycle planning for storage tank owners globally.

The global maintenance team has worked with Falcker to build best practices and now has a greater understanding of asset management practices. This has empowered Falcker to create digital solutions that improve asset integrity and lifecycle planning for storage tank owners globally.

Ready for smarter maintenance?

Let’s talk

Our Solutions are trusted by global Brands.